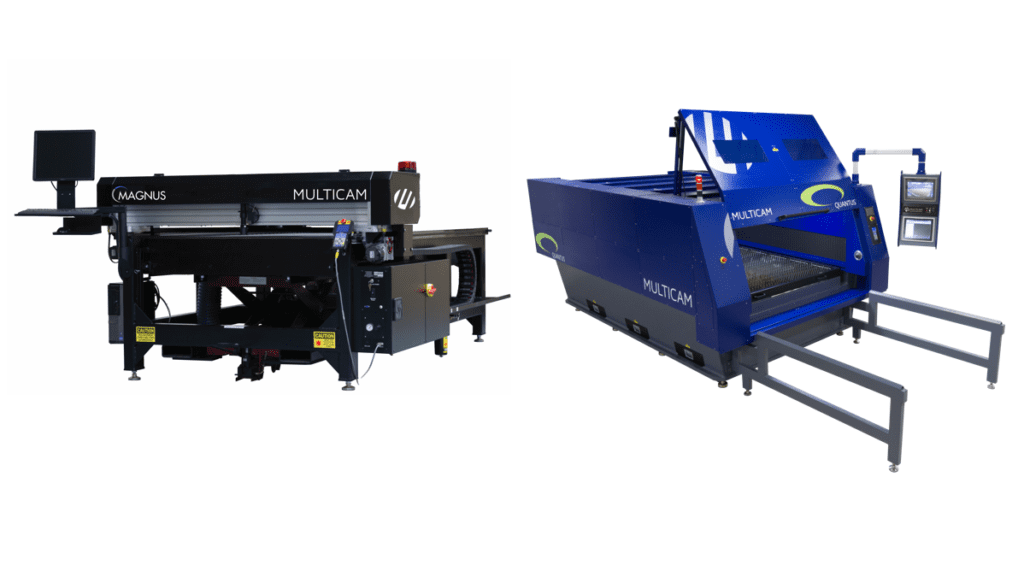

CNC PLASMAS

Conventional + High Definition

CNC plasma cutters are advanced, high-speed cutting tools that use a high-velocity jet of ionized gas, or plasma, to cut through materials into a desired shape. These machines are controlled by a computer, which allows for precise and intricate cutting patterns. They excel at cutting conductive materials, such as steel, stainless steel, aluminum, brass, and copper. With their ability to cut through thick or thin materials quickly and efficiently, CNC plasma cutters are ideal for industrial applications, automotive repair, and fabrication shops.

CNC WATERJETS

Pure Water + Abrasive

CNC waterjet machines are powerful cutting tools that utilize a high-pressure stream of water, sometimes mixed with an abrasive substance, to cut through materials. They’re controlled by computer programming, ensuring precision and consistency in all cuts. Waterjets are versatile and can cut through nearly any material, including metal, stone, glass, and composites, without generating heat, thus eliminating a heat affected zone. This makes them particularly well-suited for applications that require intricate designs and high precision, such as aerospace components, architectural applications, or fabrication shops.

CNC LASERS

CO2 + Fiber

CNC laser cutters utilize focused, high-powered laser beams to cut through materials. Controlled by a computer program, these machines offer high precision and can produce intricate cuts and designs. A CO2 laser is particularly effective at cutting materials like acrylics and woods with capabilities of cutting thinner metals. Fiber lasers are effective at cutting ferrous metals of varying thicknesses. Due to their precision and the clean, polished edges they produce, CNC laser cutters are commonly used in industries that require detailed work, such as electronics manufacturing, engraving, and the production of medical devices.